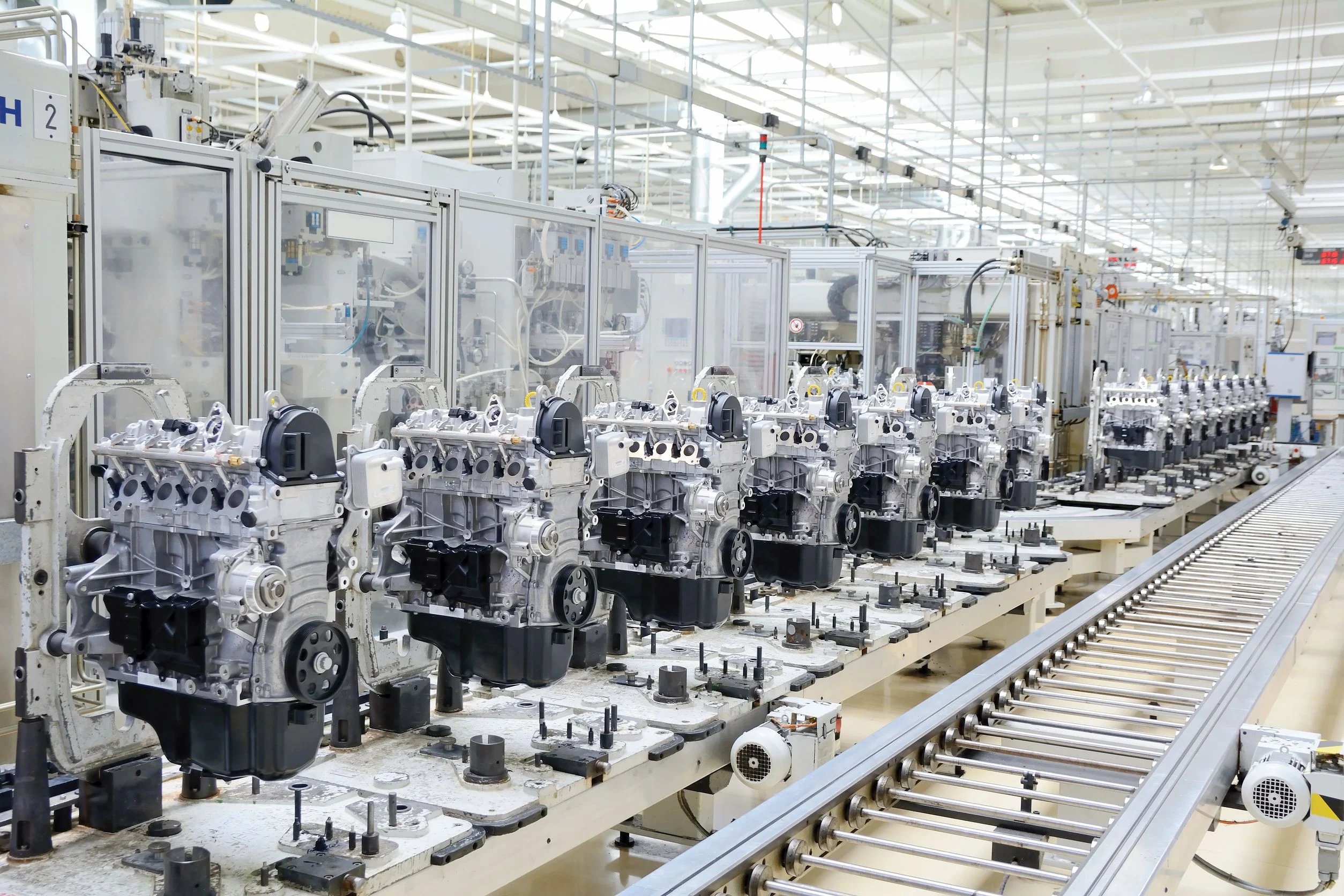

Stop unexpected breakdowns. Start predicting them.

70% of manufacturers lack predictive maintenance

Instead, they rely on outdated software, spreadsheets, and manual logs. The result? No early warnings. No standardization. Just costly, unexpected breakdowns.

Built for Giants

Existing solutions require billion-dollar budgets, massive IT teams, and years of historical data.

Frequent Downtime

Small manufacturers can't afford unexpected breakdowns, but manual checkups waste skilled labor.

No Early Warnings

Running on thin margins with aging equipment means every breakdown directly impacts revenue.

Meet Predictra: Your AI maintenance assistant

An AI-powered predictive maintenance platform specifically designed to be low-cost and applicable to all manufacturers. Upload your data, get early warnings, prevent breakdowns.

Upload

Drop in your PDFs, spreadsheets, or incomplete records. Our system handles the mess.

Get Alerts

Receive early warnings about potential equipment failures before they happen.

Take Action

Get actionable recommendations. Need a new part? It's ordered automatically.

Stay Running

Keep production smooth and avoid costly downtime with predictive intelligence.

Powered by 4 key components

Our advanced AI technology stack works seamlessly to deliver reliable predictions

Data Enrichment Engine

Converts messy PDFs, spreadsheets, or incomplete records into structured, usable datasets. No data scientist required.

Adaptive Anomaly Detection

Learns from your machine's specific patterns to detect early warning signs of failure before they become problems.

Conservative RUL Predictions

Gives underpredicted, trustworthy timelines on how long a machine has before failure. Categorized by urgency.

Continuous Intelligence

Actionable recommendations, not just numbers. If a new part is needed, it's ordered automatically. Everything displayed in one dashboard.

Textile factory saves $8,000 in downtime

A local textile factory uploaded two months of temperature and vibration logs. Predictra detected subtle bearing issues, predicted failure in 7 days, automatically scheduled maintenance, and saved them $8,000 in downtime costs.

Simple, transparent pricing

No hidden fees. No surprises. Just predictable costs that scale with your needs.

Starter

For companies with 1-10 machines. Basic maintenance tracking, AI anomaly alerts, and weekly reports.

- Up to 10 machines

- AI anomaly detection

- Weekly reports

- Email support

Enterprise

- Everything in Standard

- API access & integrations

- Custom IoT integrations

- Dedicated support

- Custom training & onboarding

Ready to prevent your next breakdown?

Join forward-thinking manufacturers who are already saving thousands with AI-powered predictions.